AUCKLAND WELDING SERVICES

Welding Services

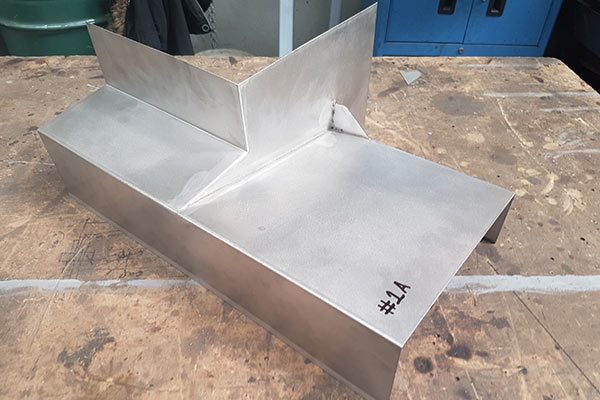

North Harbour Engineering are specialist Auckland welders with expertise and offering specialist welding services for steel, aluminium, stainless steel, structural steel, copper, brass, cast iron, and various other types of metals.

We are here to provide solutions for your steel, stainless steel, aluminium, copper and other metal welding needs, and specialise in large-run welding jobs, or one-off custom welding jobs.

Structural Welding and Custom Welding Services

From the cutting and welding of structural steel beams, to the welding of flashings and deck cappings, to the more delicate welding of one-off architectural or design pieces, we are the welders who have done it all.

We have expertise and experience in:

MIG Welding

MIG stands for Metal Inert Gas. MIG Welding allows for the welding of most robust metals such as steel and aluminium.

Advantages to MIG welding include:

- Quick welding method,

- Welds are free of spatter,

Finished welds result in low distortion of welded metals.

TIG Welding

TIG stands for Tungsten Inert Gas. TIG Welding allows for the welding of thin sections of stainless steel and non-ferrous metals such as aluminium, magnesium, and copper alloys. It enables us to create precision welds that are strong and of a high quality.

Advantages to TIG welding include:

- Extremely high-quality weld,

- The ability to make long welds without starts and stops,

- There is minimal post-weld cleaning required.

Arc Welding - On-site Welding

Arc welding works by creating an electric arc between an electrode and the base material to melt the metals at the welding point. Arc welding is ideal for welding most metals including, steel, stainless steel, cast iron welding, copper and brass. And, once it cools, the welded joint is often stronger than the base metals.

The beauty of our Arc welding service is that it can be done on-site – that means, we come to you.